ETP-HYLOC

For heavy loads and quick mounting!

ETP-HYLOC is a hydro-mechanical hub-shaft connection which, due to its robust design, is ideally suited to work in difficult environments

and heavy operations like steel rolling mills, process industries etc. An interesting application, among many, has been fastening of feeding or forming rolls to shafts.

ETP-HYLOC is fast to mount, has good concentricity and can take high torque and radial loads. Mounting and dismantling is easily carried out with a hydraulic pump.

Construction

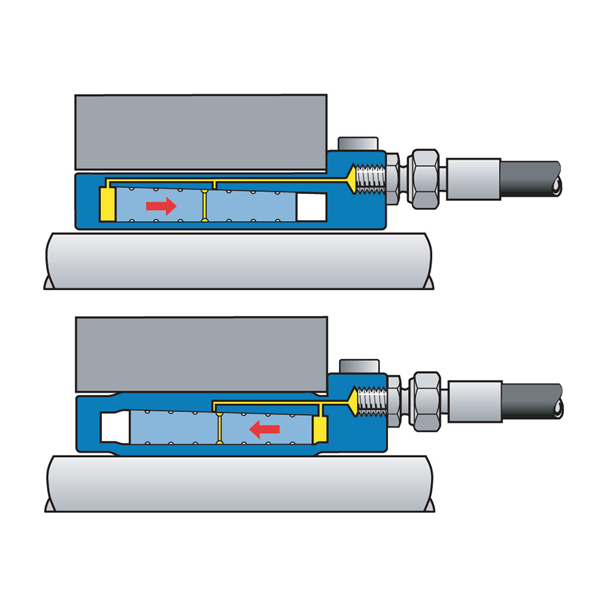

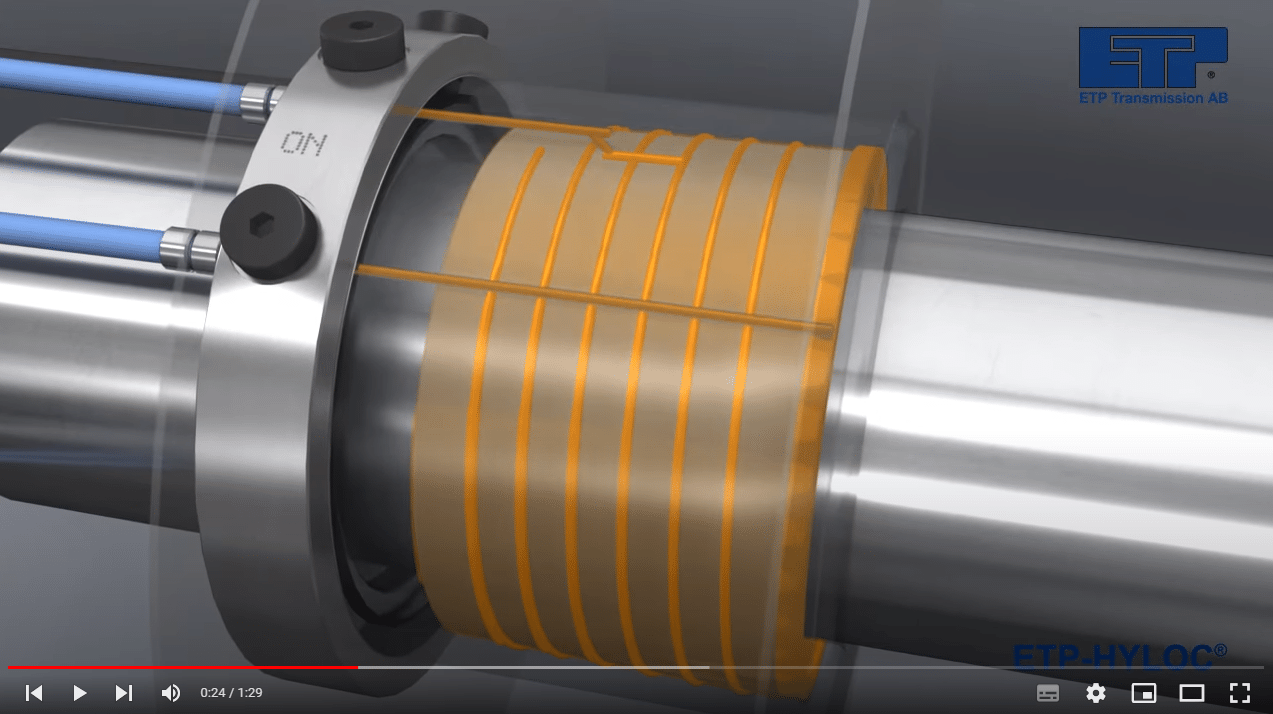

ETP-HYLOC is a hydro-mechanical joint, which consists of a double-walled steel sleeve which encloses a conical moveable piston. Mounting and dismantling is carried out with a hydraulic pump.

In the flange there are three threaded connections (”ON”, ”P” and ”OFF”) in the radial direction and the same in the axial.

This makes it possible to choose radial or axial connection of the pump hoses, depending on the build-in situation.

Operation

When the piston is moved, by the hydraulic pressure from the pump, the double-walled sleeve expands uniformly against shaft and hub to form a rigid joint.

When dismantling, the piston is moved in the opposite direction and the joint will loosen. A small amount of oil will be taken via spiral tracks in the piston

between the surfaces (pressure applied through the ”P” connection), in this way making it easier for the piston to move.

Normal working pressure is 1 000 bar.

Benefits & Features

High transmittable torque capacity - can be varied by changing the mounting pressure.

Fast mounting/dismantling in tight spaces.

High radial load capacity.

Radial and axial connection is possible.

Fine adjustments of the hub can be made when mounting.

Good concentricity, also after several mountings.

Product variants

Filter by

| Product | Availability |

Price

|

||

|---|---|---|---|---|

| ETP-HYLOC 50 |

3

|

|

||

| ETP-HYLOC 60 |

7

|

|

||

| ETP-HYLOC 70 |

0

|

|

||

| ETP-HYLOC 80 |

10

|

|

||

| ETP-HYLOC 90 |

0

|

|

||

| ETP-HYLOC 100 |

1

|

|

||

| ETP-HYLOC 110 |

0

|

|

||

| ETP-HYLOC 120 |

13

|

|

||

| ETP-HYLOC 130 |

9

|

|

||

| ETP-HYLOC 140 |

3

|

|

||

| ETP-HYLOC 150 |

2

|

|

||

| ETP-HYLOC 160 |

0

|

|

ETP Application Design Assistance form (ADA)

ETP Application Design Assistance form (ADA)