ETP-EXPRESS

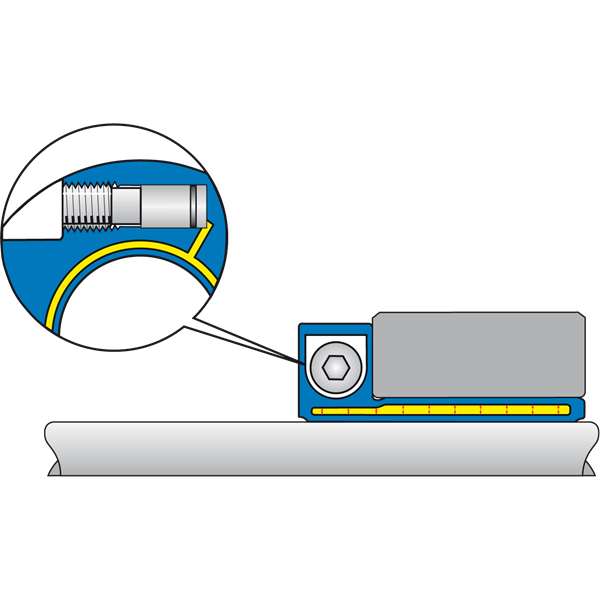

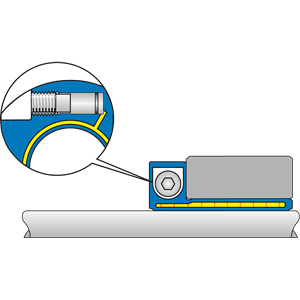

ETP-EXPRESS is a hydraulic connection which has only ONE screw for pressurising.

It is especially suitable for repositioning of the hub fast and accurately. The screw is tightened in the radial direction, this means no space is used along the shaft for mounting

tools. Other components can be mounted on the shaft all the way up to the flange. ETP-EXPRESS has extremely small built-in dimensions which makes a compact design possible.

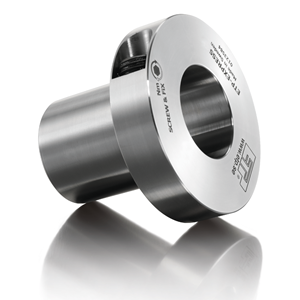

Construction

ETP-EXPRESS is a hydraulic connection which consists of a double-walled hardened steel sleeve filled with a pressure medium and a flange.

The flange part contains screw and piston with seals to maintain pressure.

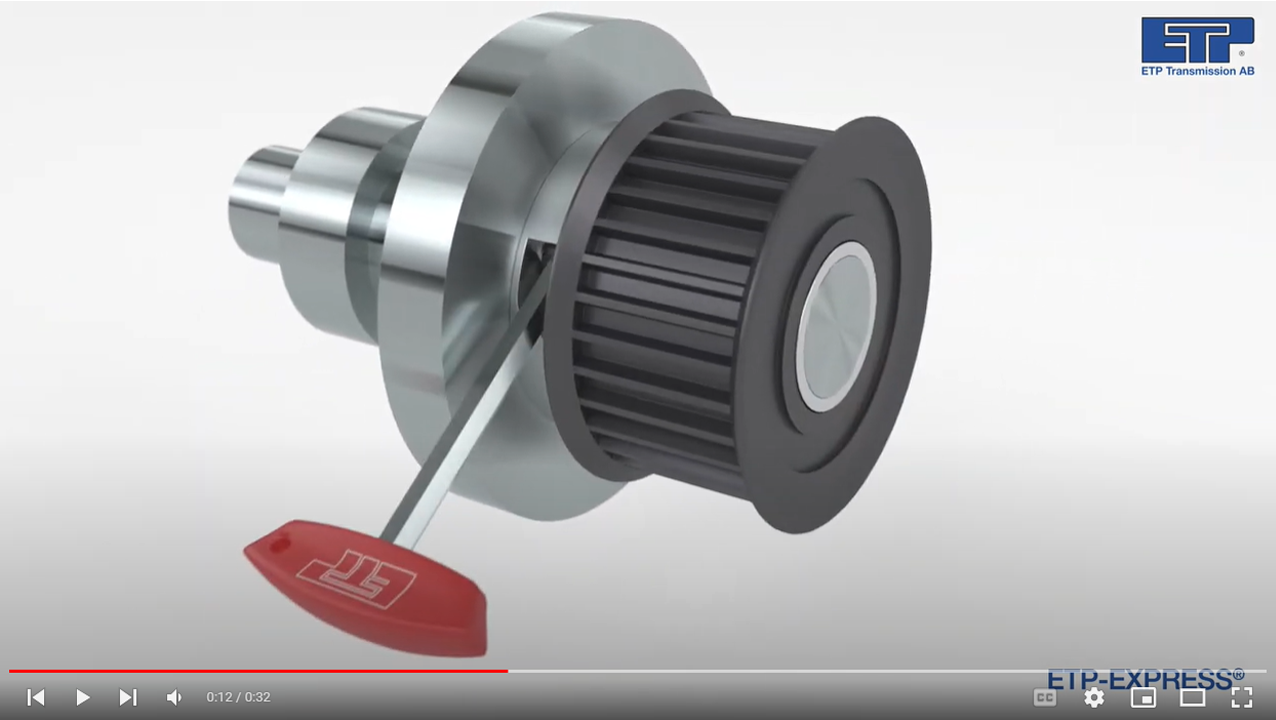

Operation

When the pressure screw is tightened, the double-walled sleeve expands uniformly against shaft and hub and creates a rigid joint.

Dismantling is done by loosening the screw. ETP-EXPRESS returns to its original dimensions and can easily be dismantled.

SUSTAINABILITY

For over a decade, ETP has maintained a strong focus on sustainability.

We've been diligently collecting data from our internal operations, and guess what? We've successfully developed a measurable indicator for the "footprint" of our products.

The ETP-EXPRESS, on average, has the same environmental impact as a Big Mac.

However, ours is fully recyclable and can be smelted down and turned back into more products after being used for years and Big Mac seem to be impervious to the effects of decay and time.

Benefits & Features

Extremely fast mounting/dismantling with only ONE screw.

Radial tightening of the screw saves space along the shaft.

Extremely small built-in dimensions.

Accurate positioning, no axial movement when mounting.

Good concentricity, also after several mountings.

Product variants

Filter by

| Product | Availability |

Price

|

||

|---|---|---|---|---|

| ETP-EXPRESS 15 |

124

|

1,887.00 SEK |

|

|

| ETP-EXPRESS 5/8" |

0

|

1,893.00 SEK |

|

|

| ETP-EXPRESS 19 |

3

|

1,896.00 SEK |

|

|

| ETP-EXPRESS 3/4" |

5

|

1,915.00 SEK |

|

|

| ETP-EXPRESS 20 |

125

|

1,950.00 SEK |

|

|

| ETP-EXPRESS 22 |

3

|

1,962.00 SEK |

|

|

| ETP-EXPRESS 7/8" |

2

|

1,972.00 SEK |

|

|

| ETP-EXPRESS 24 |

33

|

1,972.00 SEK |

|

|

| ETP-EXPRESS 25 |

76

|

2,038.00 SEK |

|

|

| ETP-EXPRESS 1" |

44

|

2,070.00 SEK |

|

|

| ETP-EXPRESS 28 |

93

|

2,129.00 SEK |

|

|

| ETP-EXPRESS 1 1/8" |

4

|

2,262.00 SEK |

|

ETP Application Design Assistance form (ADA)

ETP Application Design Assistance form (ADA)