Hub-Shaft connections

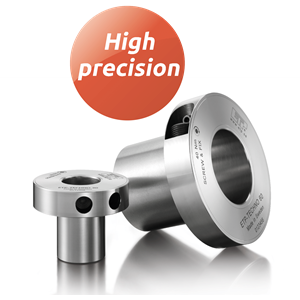

Precision connections for general machine building!

Industrial areas of use

ETP hub-shaft connections are today regarded as the natural range to choose from for professional machine design. They represent the optimal cost/performance ratio and are available in a number of variants.They operate according to either the hydraulic or hydromechanical principle, which gives unique advantages when designing, in operation and when mounting/dismantling.

Aerospace

Aerospace manufacturing is a high-technology industry and whether aircrafts, engines or related parts are made, functional safety is crucial which allows for no compromises or negligence. Our range of hydraulic high precision hub-shaft connections ensures safe and precise fastening of your critical components.

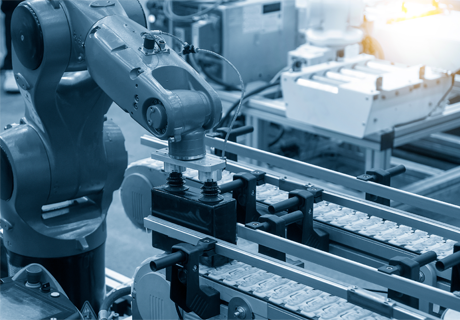

Automotive

Being one of the worlds’ largest, the automotive industry heavily relies on automated machinery and robotics with high requirements of serviceability and low downtime. Arms and levers perfectly positioned along drive shafts is easily achieved using the ETP connections and offers you the best in backlash free performance and flexibility.

Test & Laboratory

Products in development or manufacturing phases subjected to test cycles is a high requirement environment. Hardware and software tools need a high degree of reliability and flexibility. Hydraulic connections such as ETP-EXPRESS with its superfast mounting and dismantling capabilities is ideally suited.

Medical

Testing, safety and efficiency are crucial within the medical industry. Clean room and sterile conditions puts extra requirements into play when designing machinery equipment, such as surfaces and materials used. Here ETP with its extensive range of stainless hub-shaft connections contributes to new design capabilities.

Food & Beverage

Today’s food and beverage industry, from raising crops to processing foodstuffs and packaging, is a highly mechanized process. Machine design requirements include compliant materials, in particular stainless steel, and protection of drive components against aggressive cleaning agents and/or acidic agents. ETP offers fully FDA compliant hub-shaft connections for all your needs.

Material handling

Moving material from one location to another, whether conveyors, cranes, robots or pallet trucks are involved, requires precise positioning and sorting of the goods. Various moveable component part need a high level of synchronisation. The ETP range of hub-shaft connections offers exact mounting possibilities of critical components with high precision level.

Packaging & logistics

Processes in packaging machines such as supply of packaging materials, positioning of goods, grouping, shifting, labelling, sealing, and much more are closely linked and often clocked in extremely short cycles. Accuracy in these motion sequences are of great importance thus the need for backlash-free couplings are essential. The ETP range of hub-shaft connections offers you exactly these criteria.

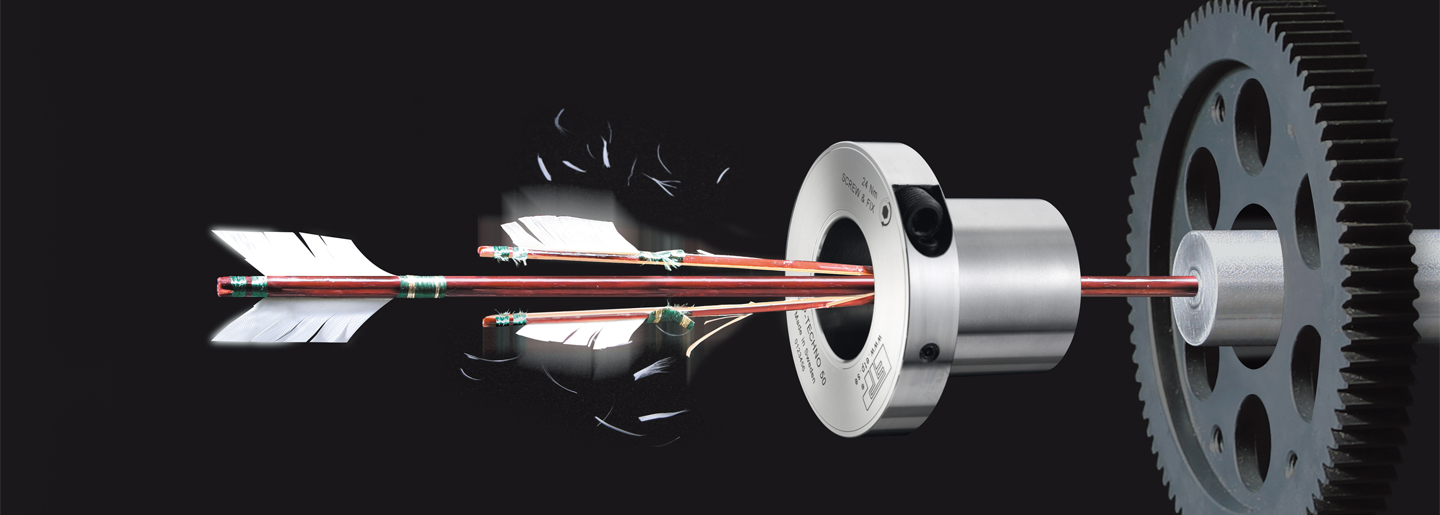

Printing & Engraving

The printing/engraving industry is a highly automated and competitive business. Post-press technology solutions such as conveying, sorting, inserting, stacking and packaging also run at high speed. Rollers and other critical components require hub-shaft connections with features of high balance degrees and excellent runout precision.

Steel & Metal

Steel & Metal industries involves characteristics such as large and heavy equipment and complex processes. A higher capital intensity puts requirements for short downtime and maintenance in focus when designing. ETP offers you a wide range of connections suited to work in difficult environments while maintaining precision and flexibility in operations.

Machine tool

Rising spindle speeds and higher precision needs, these are some essential trends in the machine tool industry. Together with more advanced feeder systems and robotic loading/unloading machining times can be reduced and machine uptime improved! Your critical components require hub-shaft connections with features of high balance degrees and excellent runout precision.

Filter by

- Total: 7

ETP-EXPRESS

From 1,887.00 SEK

ETP-TECHNO

From 5,336.00 SEK

ETP-POWER

ETP-CLASSIC

From 1,506.00 SEK

ETP-MINI

From 457.00 SEK

ETP-HYLOC

ETP-OCTOPUS

- Total: 7

ETP E-Learning

Welcome to our E-Learning platform

Here you find short courses designed to teach you more about ETP´s products an applications. Find out more on the most commonly used solutions and techniques used in today´s hub-shaft connections industry as well as the hydraulic principle upon which all ETP products are based.

Get to know our products