Best of the Best Tooling for Extremely Tight Tolerances

Medical Manufacturer Autocam Medical Chooses ETP – Requires the Best of the Best Tooling for Extremely Tight Tolerances

The leading medical manufacturer, Autocam Medical, requires extreme precision to make their products, later used by a very demanding industry that performs life-changing procedures. In February, the company made their first purchase of ETP HYDRO-FIX SWISS® and the versatility of the product makes them return, over and over again.

The American manufacturer of high-performance surgical instruments and medical tools, Autocam Medical, is a leader within the medical industry and has clients all over the world. They are based in Kentwood, Michigan, and have been a manufacturer of orthopedic implants, spinal implants, precision instruments and orthopedic cutting tools since 1993. Specialized in precision-machined surgical drill bits, drivers, screws, plates, cutting tools and other complex, highly engineered surgical implants, instruments, and handpieces, the company requires high-quality tooling for their extremely tight tolerances. Earlier this year, Seth Nickerson, Machine Technician at Autocam Medical, was tasked by his manager to investigate hydraulic holders for one of their new Swiss machines. He tried out a couple of holders, but experienced limitations with all of them. The search continued, and eventually, he found ETP Transmission, and more specifically ETP HYDRO-FIX SWISS®.

“The versatility offered by ETP is amazing. They use different-sized reduction sleeves so I can keep the holder in the machine and swap different tools for different jobs. I ran into a machine limitation issue and ETP was able to customize their holder to my needs”, Seth Nickerson says and continues:

“They also share build information so I can customize a holder without damaging the internal components. Their price is much better than the competition, and the versatility of the style of holders allows me to get tooling in tight spaces. From a safety perspective, these holders allow effortless tool changes in tight spaces without the wrenches slipping off. I can’t wait to see what they produce next. “

A Growing Partnership

Autocam Medical has been an ETP customer since February, and even if it’s a short time since their first purchase, their Field Sales Engineer from ETP Transmission Inc., Jay Reynolds, is very pleased with the cooperation so far.

“The cooperation with Autocam Medical has been great. They are not afraid to ask if they can do things to modify our holders to better suit their needs. They have had some great innovative ideas that have helped us develop new products that will not only benefit them but other customers that face similar challenges”, Jay Reynolds says before he concludes:

“The medical industry is a large user of our Swiss product. Having a leading medical manufacturer, in close proximity to home, that is both innovative and creative in developing things to make their manufacturing easier and more productive is a great help for us as we develop new products. I hope that our partnership continues to grow and that our success expands to their other facilities around the world.”

The versatility offered by ETP is amazing and from a safety perspective, these holders allow effortless tool changes in tight spaces without the wrenches slipping off. I can’t wait to see what they produce next.

Choice of product for Autocam Medical

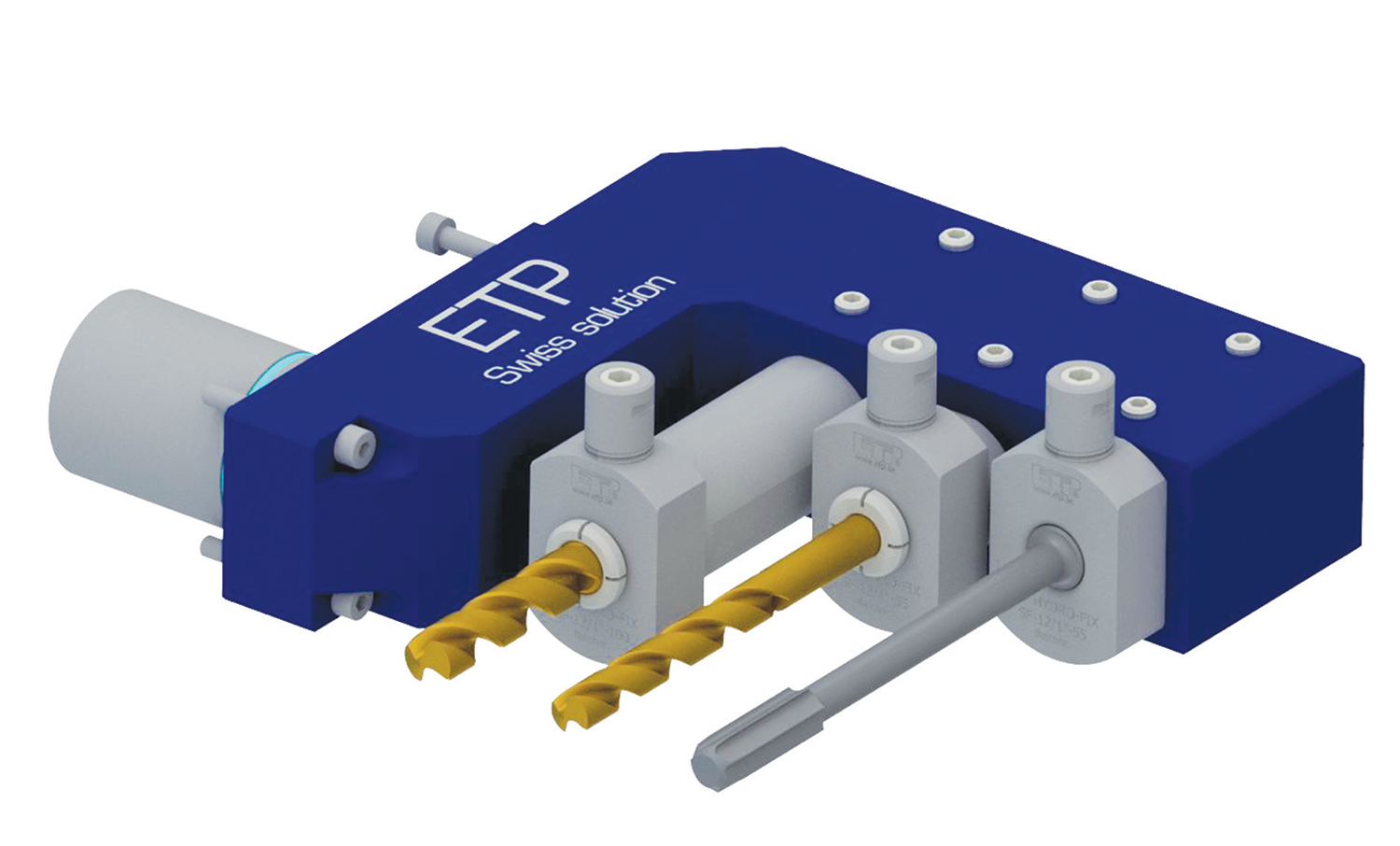

ETP HYDRO-FIX SWISS precision toolholders

ETP HYDRO-FIX SWISS clamping units are excellent for static front and back operations such as drilling, reaming and boring. With the one screw fix system it is quick and easy to handle. Precision hydraulic tool centering is achived and therefore the tool life and setup time is improved. The clamping unit allows for larger/deeper drilling, quick tool changes, absorbs/reduces vibration, improves suface quality and best of all – Increases your productivity!

More about HYDRO-FIX SWISS precision holders