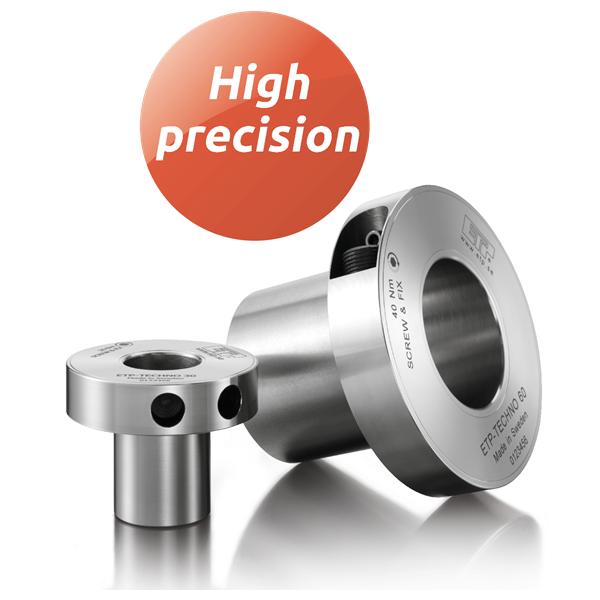

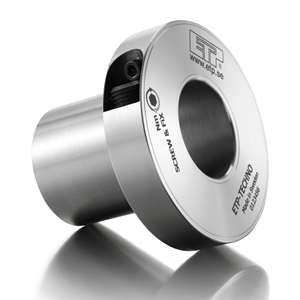

ETP-TECHNO

ETP-TECHNO is a hydraulic connection with very high precision.

It is especially designed for applications where fast frequent changes or adjustments, with high precision are needed. It can be mounted/dismantled 1000´s of times

ETP-TECHNO is very easy to mount with only one screw, and it also has extremely good concentricity and is the one to choose among the ETP hub-shaft connections when very high precision is needed.

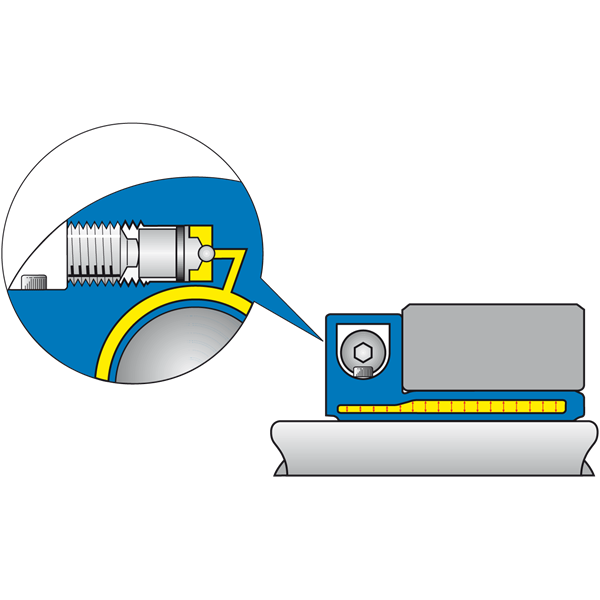

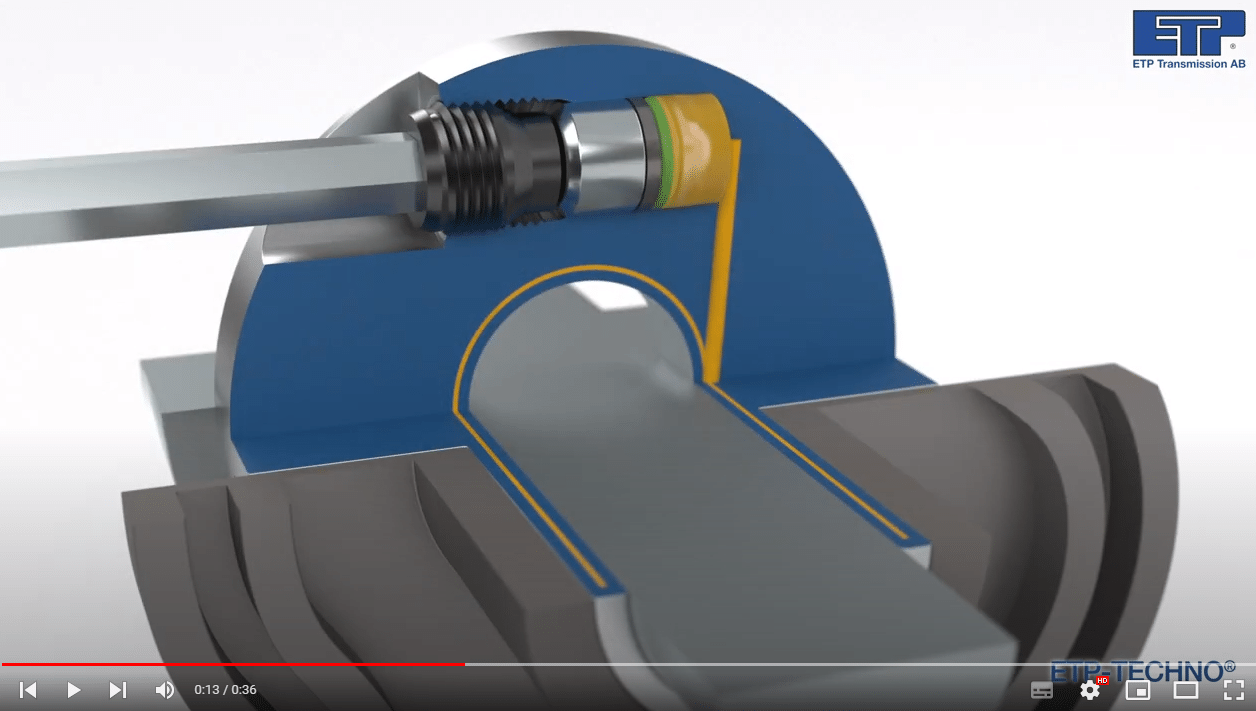

Construction

ETP-TECHNO is a hydraulic connection which consists of a double-walled hardened steel sleeve filled with a pressure medium, and a flange.

The flange contains the pressure screw and piston with dual sealing function

- an o-ring plus backup ring and a steel ball.

Operation

When the pressure screw is tightened, the double-walled sleeve expands uniformly against the shaft and the hub and creates a rigid joint.

Dismantling of the joint is simply done by loosening the screw. ETP-TECHNO returns to its original measurements and can easily be dismantled.

Benefits & Features

Extremely fast mounting/dismantling with only ONE screw.

Can be mounted/dismantled 1000´s of times.

Extremely good concentricity, ≤ 0.006 mm, also after several mountings.

Dual sealing system.

Radial tightening of the screw saves space along the shaft.

Accurate positioning, no axial movement when mounting.

Product variants

Filter by

| Product | Availability |

Price

|

||

|---|---|---|---|---|

| ETP-TECHNO 15 |

17

|

5,336.00 SEK |

|

|

| ETP-TECHNO 20 |

30

|

5,777.00 SEK |

|

|

| ETP-TECHNO 25 |

5

|

5,899.00 SEK |

|

|

| ETP-TECHNO 30 |

19

|

6,606.00 SEK |

|

|

| ETP-TECHNO 32 |

0

|

6,716.00 SEK |

|

|

| ETP-TECHNO 35 |

13

|

6,867.00 SEK |

|

|

| ETP-TECHNO 40 |

4

|

7,149.00 SEK |

|

|

| ETP-TECHNO 45 |

3

|

8,178.00 SEK |

|

|

| ETP-TECHNO 50 |

0

|

8,684.00 SEK |

|

|

| ETP-TECHNO 60 |

0

|

10,107.00 SEK |

|

|

| ETP-TECHNO 70 |

0

|

12,160.00 SEK |

|

|

| ETP-TECHNO 75 |

0

|

14,088.00 SEK |

|

ETP Application Design Assistance form (ADA)

ETP Application Design Assistance form (ADA)