ETP-OCTOPUS

For fast, frequent and accurate linear positioning!

The hydraulic connection ETP-OCTOPUS is suitable when repositioning of machine parts are going to be done frequently,

fast and with high precision along the shaft, for example in machine tools for qualified machining or forming of steel.

With the use of an external hydraulic pressure source one or several connections can be clamped or loosened simultaneously!

Construction

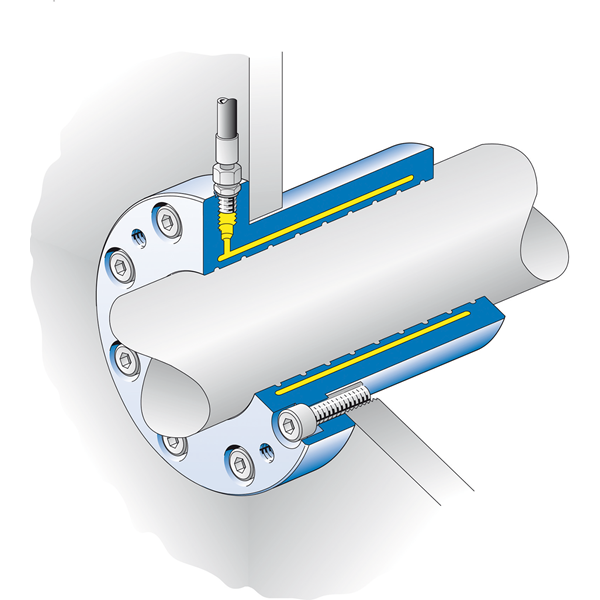

ETP-OCTOPUS is a hydraulic connection which consists of a double-walled hardened steel sleeve with a flange.

In the flange there are bores for mounting of a hub and a scraper with a screw joint, threaded connection for hydraulic oil and an air relief screw.

The inner diameter has spiral tracks in order to get an even friction and a defined locking force to the shaft.

Operation

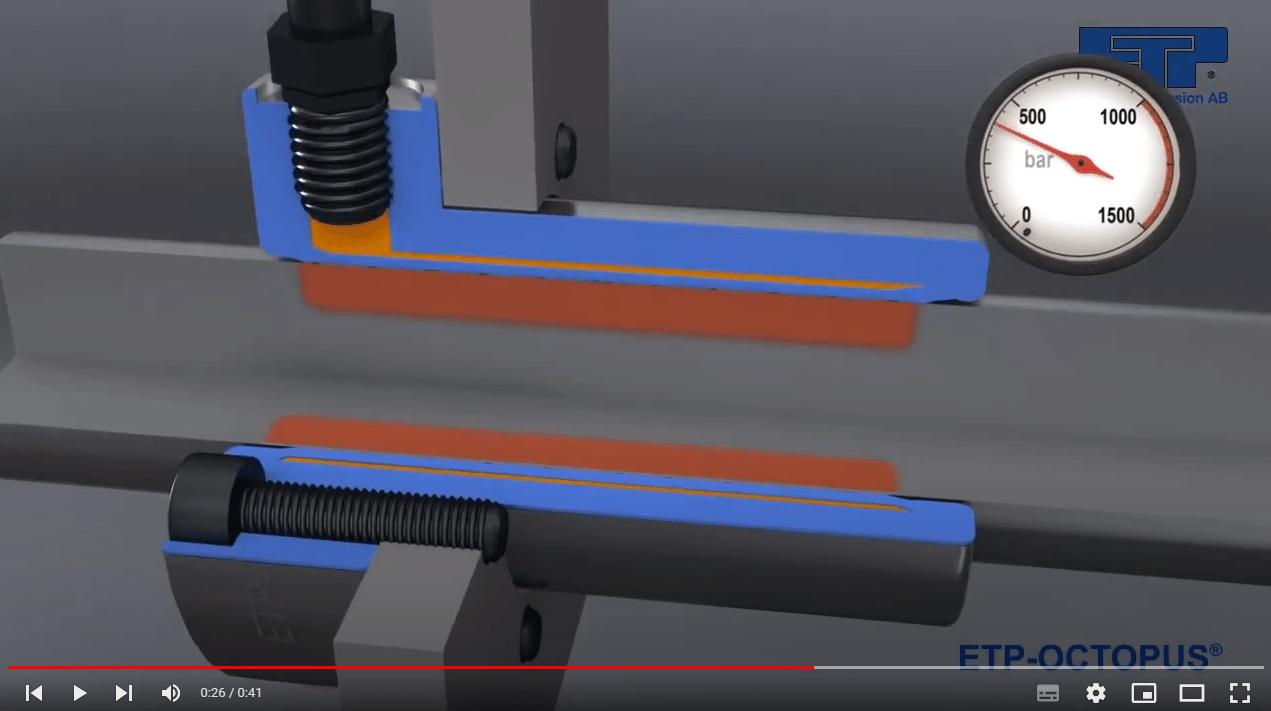

The assembly of the hub is done with the screw joint. When hydraulically pressurized the inner sleeve expands uniformly against the shaft and creates a rigid joint.

The sleeve does not expand to the outside.

When the pressure is released the sleeve returns to its original size and can then easily be moved along the shaft to its new position and be re-pressurized.

Benefits & Features

Easy to build in.

Fast and accurate positioning.

Allows up to 500 000 pressure settings

High torsional stiffness.

Both axial force and torque can be transmitted.

Product variants

Filter by

- Total: 10

| Product | Availability |

Price

|

||

|---|---|---|---|---|

| ETP-OCTOPUS 30 |

4

|

|

||

| ETP-OCTOPUS 35 |

0

|

|

||

| ETP-OCTOPUS 40 |

2

|

|

||

| ETP-OCTOPUS 45 |

1

|

|

||

| ETP-OCTOPUS 50 |

2

|

|

||

| ETP-OCTOPUS 60 |

3

|

|

||

| ETP-OCTOPUS 70 |

4

|

|

||

| ETP-OCTOPUS 80 |

3

|

|

||

| ETP-OCTOPUS 90 |

3

|

|

||

| ETP-OCTOPUS 100 |

0

|

|

- Total: 10

ETP Application Design Assistance form (ADA)

ETP Application Design Assistance form (ADA)