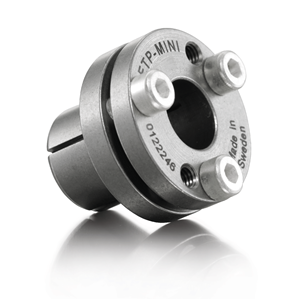

ETP-MINI

Quick compact fastening of small components!

ETP-MINI is a mechanical connection which is the best choice for mounting small components quick and easy.

Far superior to keyways or setscrews as it gives an adjustable, backlash free joint.

ETP-MINI is also available in stainless, type R, suitable for the food and medical industries!

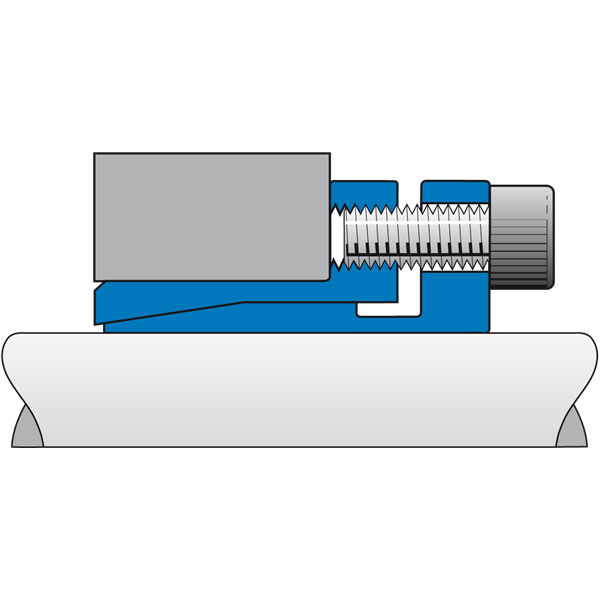

Construction

ETP-MINI is a mechanical connection which consists of two, partly slotted, conical steel sleeves (type R stainless) and cap head clamping screws (type R stainless).

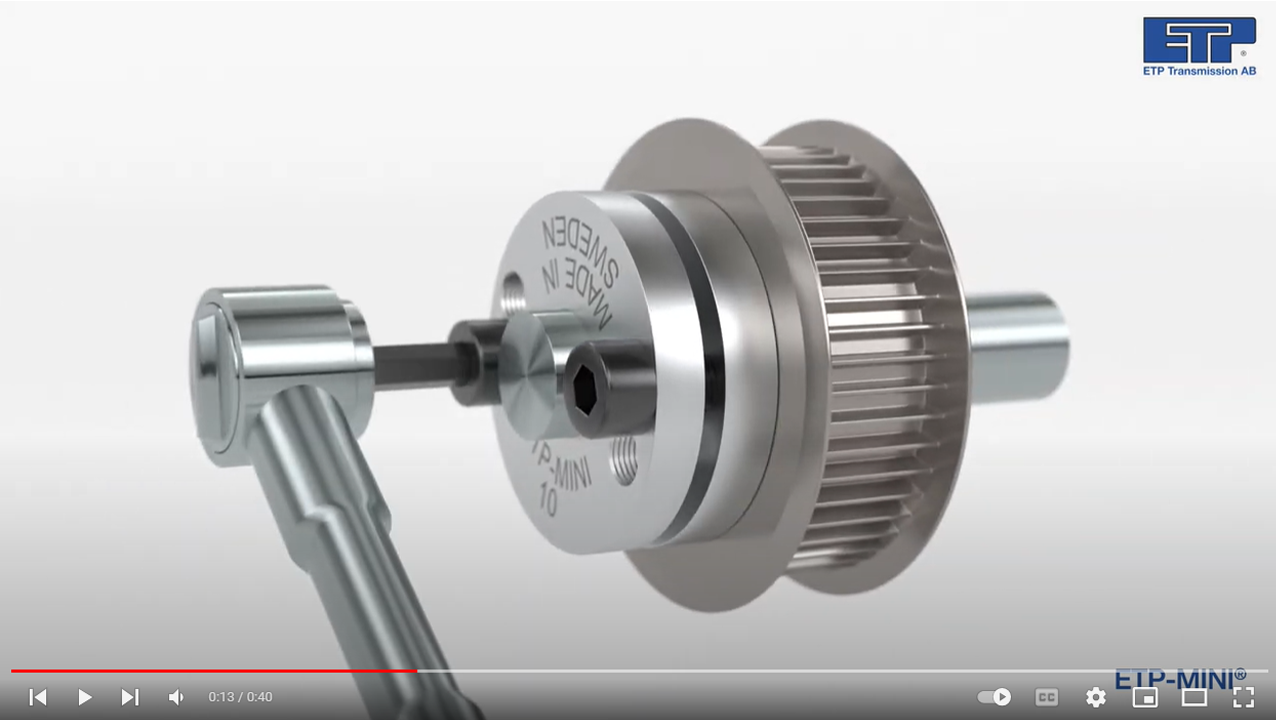

Operation

By tightening the screws, the inner sleeve is pressed against the shaft and the outer sleeve against the hub, thus forming a rigid joint.

When dismantling one, or if necessary, two of the screws are moved to the threaded dismantling holes in the flange.

By tightening, the sleeves will separate and the joint will easily loosen.

ETP-MINI type R has one screw more than ETP-MINI in order to transmit the same torque (lower tightening torque for stainless screws).

Benefits & Features

Quick and easy mounting.

Good runout.

Allows wide tolerances.

Available in stainless steel (type R).

For ETP-MINI R – stainless hex head screws available as accessories.

Product variants

Filter by

| Product | Availability |

Price

|

||

|---|---|---|---|---|

| ETP-MINI 6 |

31

|

457.00 SEK |

|

|

| ETP-MINI 8 |

141

|

473.00 SEK |

|

|

| ETP-MINI 9 |

108

|

495.00 SEK |

|

|

| ETP-MINI 10 |

0

|

501.00 SEK |

|

|

| ETP-MINI 11 |

36

|

523.00 SEK |

|

|

| ETP-MINI 12 |

0

|

558.00 SEK |

|

|

| ETP-MINI 14 |

119

|

592.00 SEK |

|

|

| ETP-MINI 1/4" |

0

|

457.00 SEK |

|

|

| ETP-MINI 3/8" |

235

|

501.00 SEK |

|

|

| ETP-MINI 1/2" |

201

|

558.00 SEK |

|

|

| ETP-MINI R-6 |

197

|

693.00 SEK |

|

|

| ETP-MINI R-8 |

94

|

728.00 SEK |

|

ETP Application Design Assistance form (ADA)

ETP Application Design Assistance form (ADA)